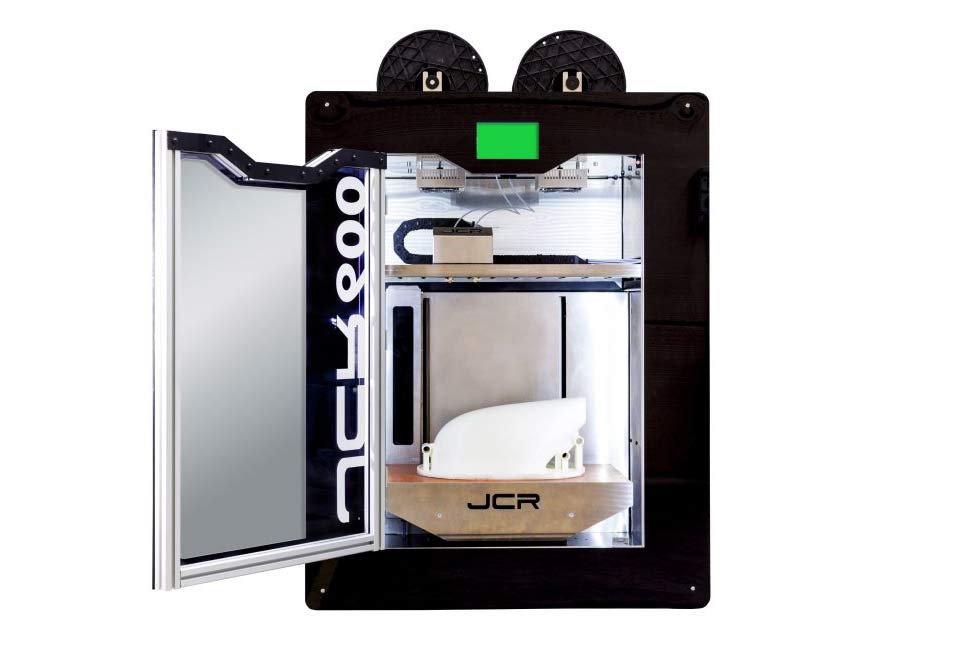

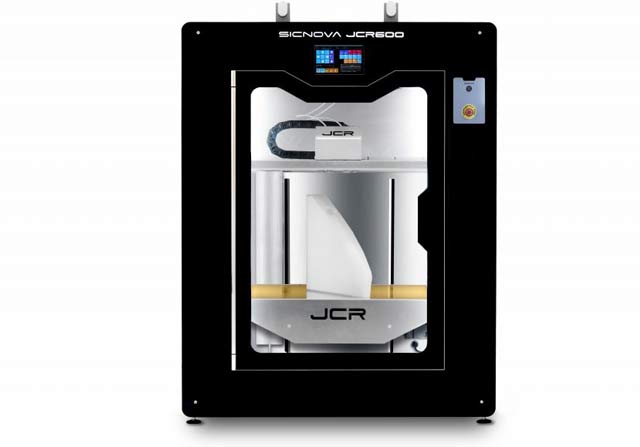

JCR 600

The ideal industrial 3D printers for standard materials.

Large size and high de nition. From small and fast models with de ned details to large pieces, with a printing tray of 580x400x500 mm and interchangeable nozzles from 0.2 to 0.8 mm, for different qualities and nishes.

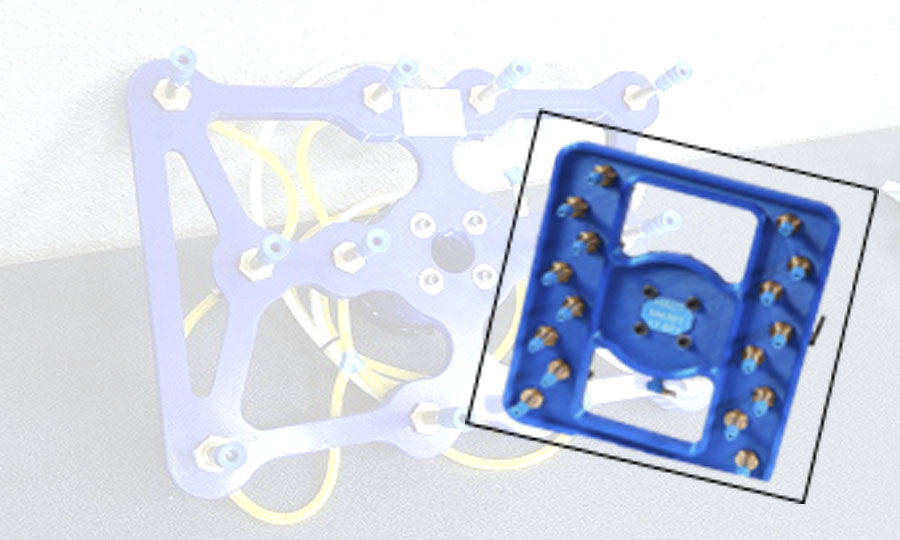

Double tilting extruder to work with double material in a stable and reliable way.

Guaranteed user experience. Guaranteed printing experience with JCR 600 for standard materials: PLA, JCR Print, FLEX – TPU and PVA.

This equipment is upgradeable to JCR 600 Pro.