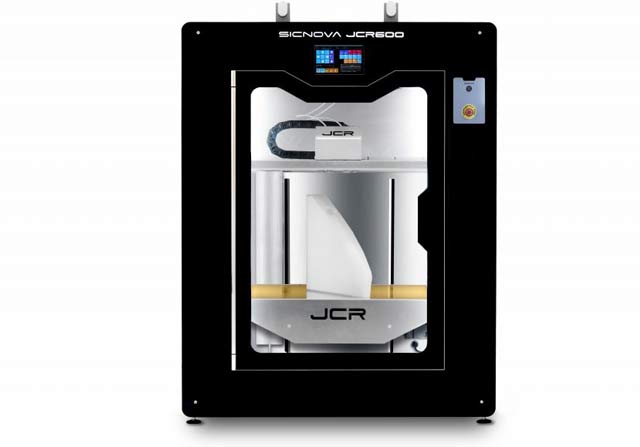

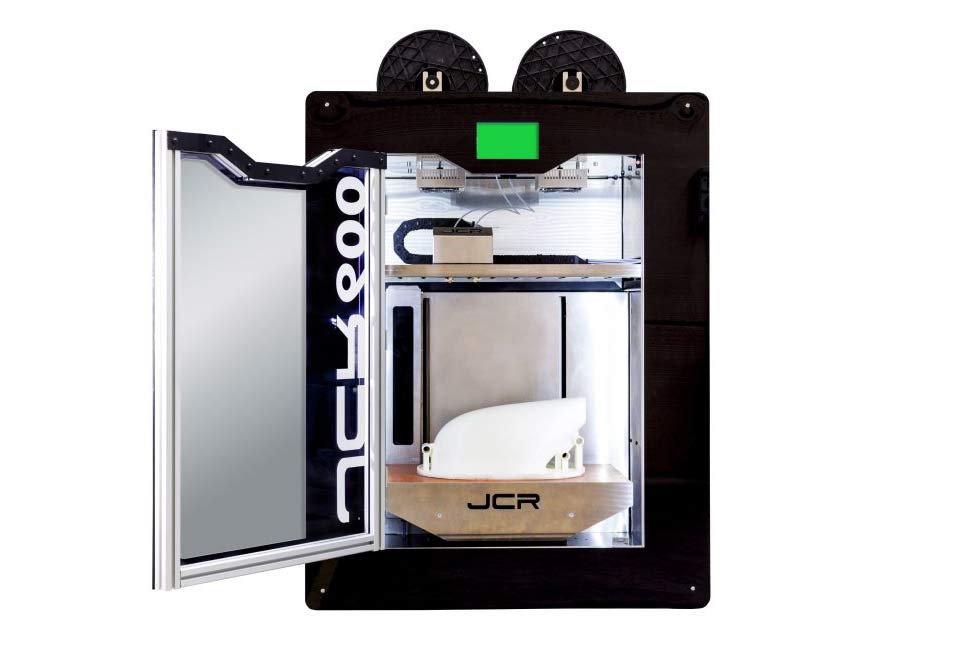

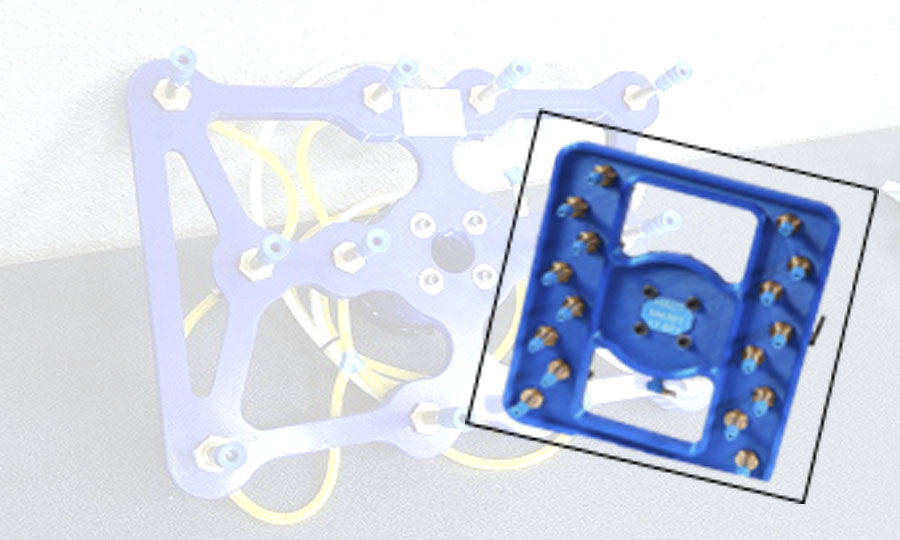

JCR 600 Pro

The ideal industrial 3D printers for technical materials

Large size and high de nition. From small and fast models with de ned details to large pieces, with a printing tray of 580x400x500 mm and interchangeable nozzles from 0.2 to 0.8 mm, for different qualities and nishes.

Double extruder up to 500 ºC maximum temperature.

Guaranteed user experience. Easy manufacturing with the most complex and technical materials that you could choose (open material), with JCR 600 Pro: PC, ABS, Nylon, CFR Nylon, ABS medical, ABS HI, Flex, JCR Print, PVA, PLA…